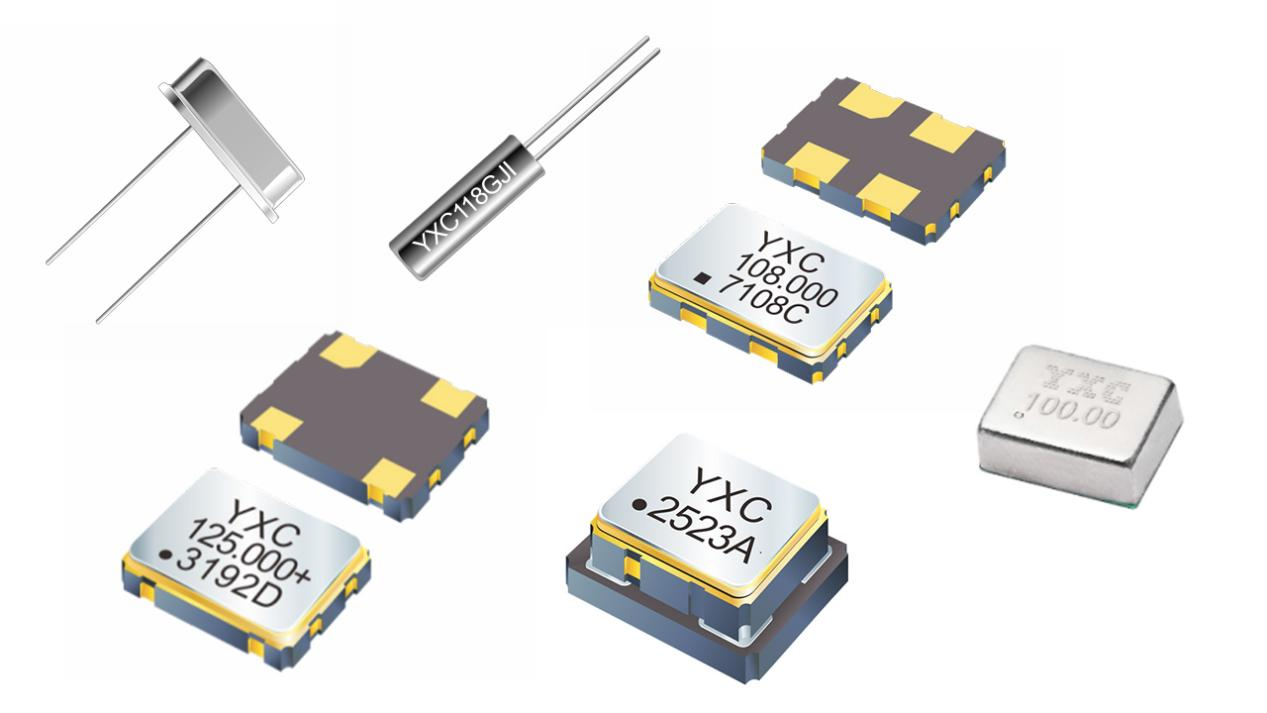

How much do you know about crystal oscillator aging? Crystal oscillators undergo anti-aging treatment during manufacturing. There are two types of crystal oscillators: crystal resonators and crystal oscillators. Both types require anti-aging treatment during production, but these treatments differ.

Aging, as the name suggests, refers to the frequency change of a quartz crystal resonator over a specific time period, expressed in parts per million. A nonlinear time-varying model has been proposed to predict the frequency aging of quartz crystal oscillators.

The frequency aging rate of a crystal oscillator refers to the relationship between the oscillator frequency and time when the oscillator frequency is measured under constant environmental conditions. This long-term frequency drift is caused by the slow changes in the quartz crystal element and the surface-mount oscillator circuit elements; therefore, the rate of frequency shift is called the aging rate.

After crystal resonators are manufactured, they require high-temperature aging, typically for 3 days. Crystal oscillators, on the other hand, are typically powered on for 3 days and then tested for 7 days. Crystal resonators are simpler, while crystal oscillators require observation and recording under voltage, thus taking longer.

All items have a wear and tear rate. Some items improve with age, while others are nearing the end of their lifespan. Crystal oscillators are no exception. What measures can be taken to effectively prevent aging during use?

1. Ensure the cleanliness of the electronic component chips. Quartz crystal oscillator chips should be thoroughly cleaned multiple times. Avoid touching them with bare hands to prevent corrosion from sweat. Wear anti-static gloves to prevent static electricity. In production workshops, anti-static clothing and shoes are also used.

2. For manufacturing plants, minimize the exposure time of electrodes to air to prevent recontamination of the chips. Ensure proper vacuum levels during coating and fine-tuning. Ion bombardment cleaning is recommended before coating. During coating, the temperature of the chip and the sputtering speed both affect electrode quality. However, there is a certain probability of stress, contaminants, residual gases, and structural defects during production.

3. Before and after coating, and after adhesive dispensing and slightly thickening, high-temperature baking should be performed to eliminate the effects of stress. Baking and aging are best carried out in a vacuum-sealed, nitrogen-filled oven. ‘’

4. Contaminants and residual gas molecules can deposit on the crystal wafer or oxidize the crystal electrodes. The higher the oscillation frequency and the thinner the crystal wafer used, the more severe this effect will be. This effect takes a considerable amount of time to stabilize. To prevent electrode oxidation, the crystal oscillator housing should be filled with high-purity nitrogen to ensure high sealing and low leakage rate.

5. For end users, when using crystal oscillators, parameters such as frequency and temperature should not exceed or be approximately equal to the crystal oscillator's limits. Exceeding these limits can easily damage the crystal and significantly impact its aging.

6. Using crystal oscillators in special environments, especially the excitation power, also affects the aging of surface-mount crystal oscillators. Higher excitation power leads to faster aging. During processing, the exposure time of the electrodes to air should be minimized to prevent recontamination of the wafer.